Let Keystone do the heavy lifting.

You’ve created an impactful product and your sales strategy is working. It’s time to produce product. Keystone is your turnkey resource for getting your product on the shelf and in your customers’ hands. Maximize your resources and focus on growing your business by leveraging Keystone for your sourcing, assembly, kitting, converting, sterilization, pilot or dunnage builds and packaging needs.

Prefer to offload your assembly and packaging?

Keystone can partner with you to convert, assemble, kit, package and sterilize your medical devices.

Explore all the ways we can serve you.

Our Focus

Our primary focus is the manufacturing, assembly, converting and kitting of sterile, single-use disposable devices.

Market Areas Include:

Wound Care

Imaging Products

Diagnostic Devices

Therapeutic Devices

Our business model is tailored to meet your needs at virtually any level of production volume.

Program production volumes range from tens of units per month to tens of thousands of units per month. We manage the entire supply chain, assist with sterilization validation and management, and provide warehousing and distribution services as needed by our clients.

In many cases, we also qualify and manage suppliers and materials that are provided by our clients. For Manufacturing Transfer Programs, clients can also leverage our Customer Product Transfer process (CPT). The CPT process provides an efficient, compliant and effective means to transfer your program to Keystone.

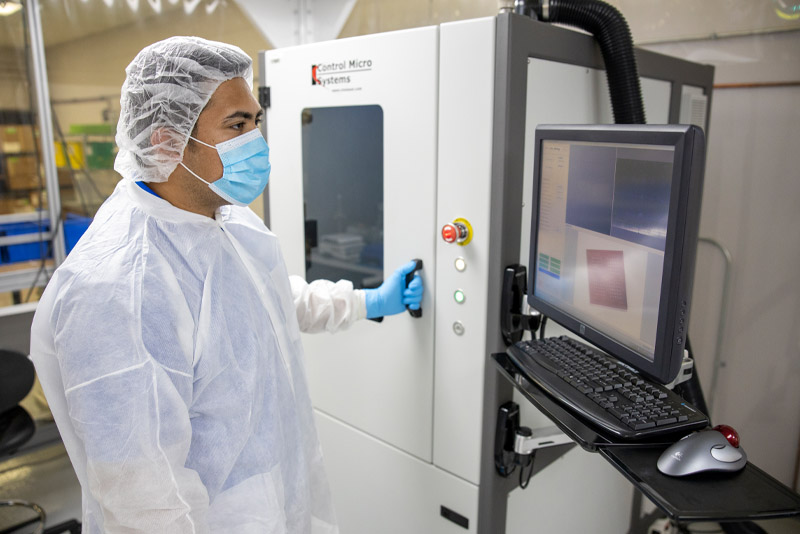

Assembly

- Kitting

- Light Assembly

- Plastic Laser Welding

- Soldering

- Adhesive Bonding

Packaging

- Sterile Barrier Packaging

- Form Fill Seal Capabilities

- Band, Bar, and Vacuum Sealing

- Tray Sealing

- Final Pack

Testing & Sterilization

- Package integrity testing (burst, creep, peel, dye penetration, bubble leak)

- Sterilization validation development and management (EO, and Gamma)

- End of line product testing

- Proprietary validated sterilization cycle

Converting

- Multi-Web

- Heat Sealing

- Thermoforming

- Die Cutting

- Custom Packaging

Warehousing & Distribution

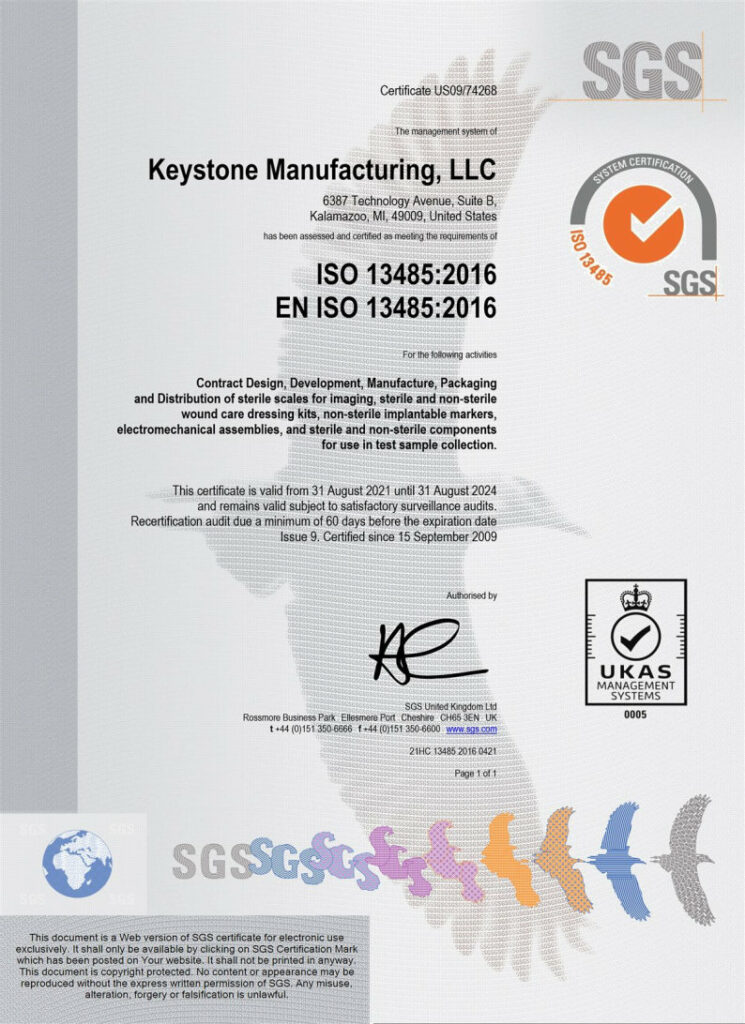

FDA registered, ISO13485:2016 certified.

Keystone delivers results utilizing state of the art 90,000 sq. ft. facilities which includes multiple controlled environments including a Class 5 final assembly area and four Class 8 clean rooms, extensive assembly and packaging capabilities. Keystone utilizes a rigorous Quality Management System to ensure the highest level of product quality. Keystone is FDA registered, ISO13485:2016 certified. Why is this important? Our certifications are an example of our commitment to quality and robust processes for delivering safe, effective medical devices on a consistent basis.

Our Approach

Keystone engages each and every client first and foremost as your advisor and partner.

Our primary goal is a successful launch of your program.

Whether you are starting with a sketch on a napkin, or exploring the option of transferring your current manufacturing program, we can help. This holistic approach has proven to be successful over the last 20+ years and provides an effective, comprehensive resource for you and your team.